In industrial settings where precision and accuracy are paramount, having reliable tools is essential. One such tool that plays a critical role in various industries is the NTEP counting scale.

These scales are not just about weighing items; they are about ensuring that every count is accurate and reliable, which can have a significant impact on operations and profitability.

In this article, we’ll explore the importance of NTEP counting scales, their key features, applications, and benefits.

What Are NTEP Counting Scales?

Definition and Purpose

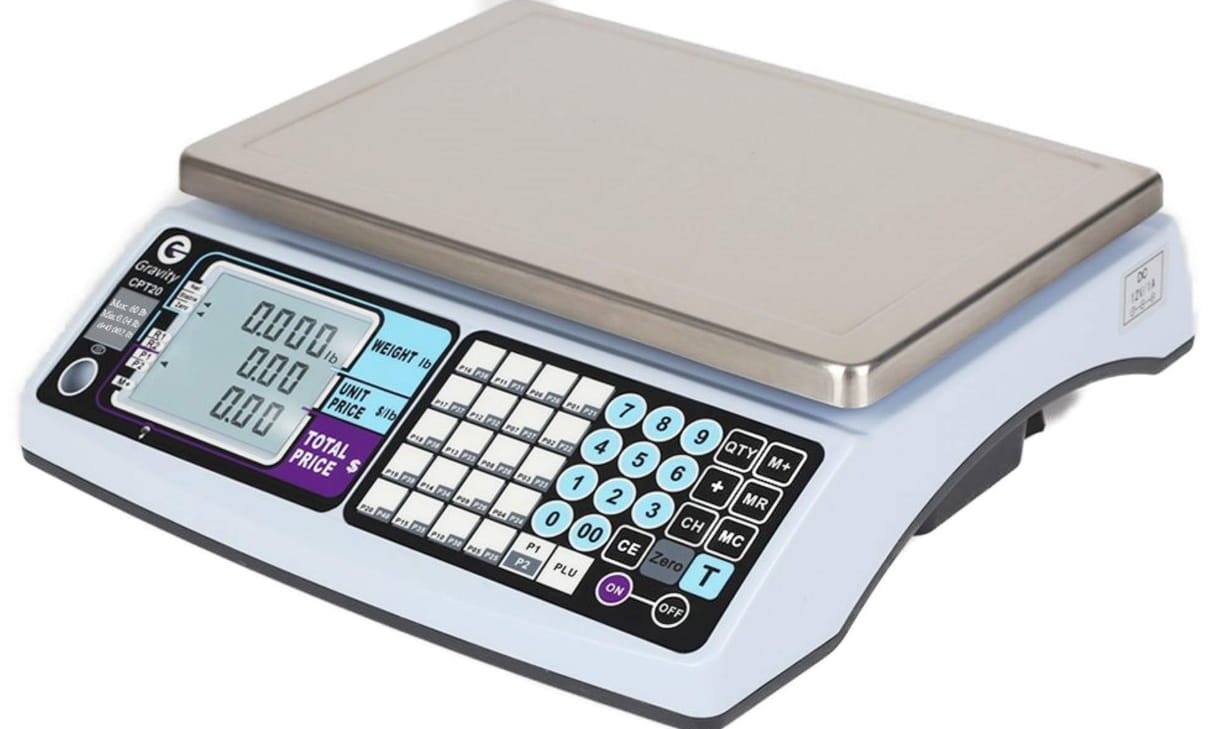

NTEP stands for National Type Evaluation Program, which is a certification process ensuring that weighing and measuring devices meet stringent standards. An NTEP counting scale is specifically designed to count pieces based on weight, providing precise and accurate counts of items, which is crucial in many industrial applications.

These scales are essential for tasks where knowing the exact number of items is more critical than just knowing the total weight, such as in manufacturing or inventory management.

Certification and Standards

The certification process for the NTEP counting scale involves rigorous testing to ensure they meet the standards set by the National Conference on Weights and Measures (NCWM).

This certification guarantees that the scales are reliable and accurate, providing users with confidence in their measurements. The standards cover various aspects, including accuracy, repeatability, and environmental factors, ensuring that the scales perform consistently under different conditions.

Key Features of NTEP Counting Scales

Accuracy and Precision

One of the standout features of NTEP scales is their high level of accuracy and precision. These scales can detect even the smallest variations in weight, allowing for precise counting of items. This is particularly important in industries where even a slight discrepancy can lead to significant issues, such as in pharmaceuticals or electronics manufacturing.

Durability and Reliability

These scales are built to last and are designed to withstand the rigours of industrial environments. They are typically constructed from durable materials that can handle heavy use and resist wear and tear.

This reliability ensures that the scales provide consistent performance over time, reducing the need for frequent replacements or repairs.

Ease of Use

Despite their advanced capabilities, NTEP scales are designed to be user-friendly. They often come with intuitive interfaces and simple controls, making them easy to operate even for users with minimal training. Features such as automatic calibration and tare functions further enhance their usability, allowing for quick and accurate measurements.

Applications of NTEP Counting Scales

Manufacturing Industry

In the manufacturing industry, NTEP counting scales are indispensable for inventory management and quality control. They ensure that the correct number of components is used in production processes, preventing errors and reducing waste.

This accuracy helps maintain product quality and consistency, which is vital for maintaining a good reputation and customer satisfaction.

Logistics and Warehousing

NTEP counting scale is also crucial in logistics and warehousing, where they help track shipments and manage stock levels accurately. By providing precise counts of items, these scales ensure that inventory records are accurate, which is essential for efficient operations.

This accuracy helps avoid stockouts and overstock situations, optimizing inventory levels and improving overall efficiency.

Retail Sector

In the retail sector, accurate product counting and pricing are critical. NTEP counting scales help retailers ensure that they are charging customers correctly and managing inventory effectively. This is especially important for small items sold in bulk, where manual counting would be impractical and prone to errors.

Benefits of Using NTEP Scales

Cost Efficiency

Using the NTEP counting scale can lead to significant cost savings by reducing errors and improving efficiency. Accurate counting helps avoid overproduction and waste, while precise inventory management prevents stockouts and reduces holding costs. These savings can add up, providing a substantial return on investment.

Compliance with Regulations

Compliance with industry regulations is crucial for avoiding fines and maintaining a good reputation. NTEP certification ensures that counting scales meet the necessary standards, providing confidence that measurements are accurate and compliant. This compliance is particularly important in regulated industries such as pharmaceuticals and food production.

Enhanced Productivity

By streamlining operations and reducing the time spent on manual counting, NTEP counting scales can significantly enhance productivity. Workers can focus on more value-added tasks, while the scales handle the counting accurately and efficiently. This improved productivity can lead to faster turnaround times and higher throughput, benefiting the overall business performance.

Conclusion

In conclusion, these scales are vital tools in various industrial applications, providing accurate and reliable measurements that are essential for efficient operations. Their key features, including accuracy, durability, and ease of use, make them indispensable in the manufacturing, logistics, and retail sectors.

By investing in these scales, businesses can achieve cost efficiency, compliance with regulations, and enhanced productivity, ultimately leading to better performance and profitability.