Laser punching and cutting are not replacing the old metal fabrication methods due to their extraordinary efficiency and benefits. Although different metal cutting methods are common in many industries, every industry is gradually adapting to this new cutting and punching method.

This article will briefly discuss the key benefits of using laser machines for cutting and punching are.

Faster cutting

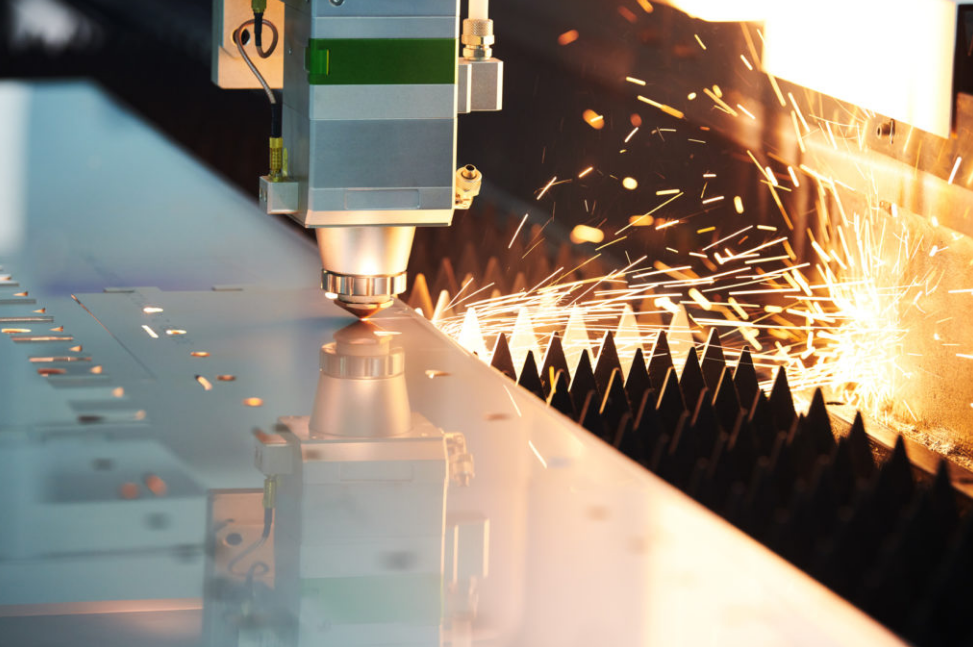

Laser cutting is comparatively much faster than other cutting techniques. It doesn’t matter which type of metal you want to cut. Laser cutting can do the job in the minimum time possible with maximum accuracy. When you cut thick materials from the lasers, it consumes more time. Still, it is rapid compared to other options.

For every kind of cutting or punching operation, you should use laser cutters and punching machines as they shorten the production time. So, for your large-scale industry where you continuously need to cut different kinds of metals, you must use laser cutters as they can reduce a significant amount of time.

Accuracy

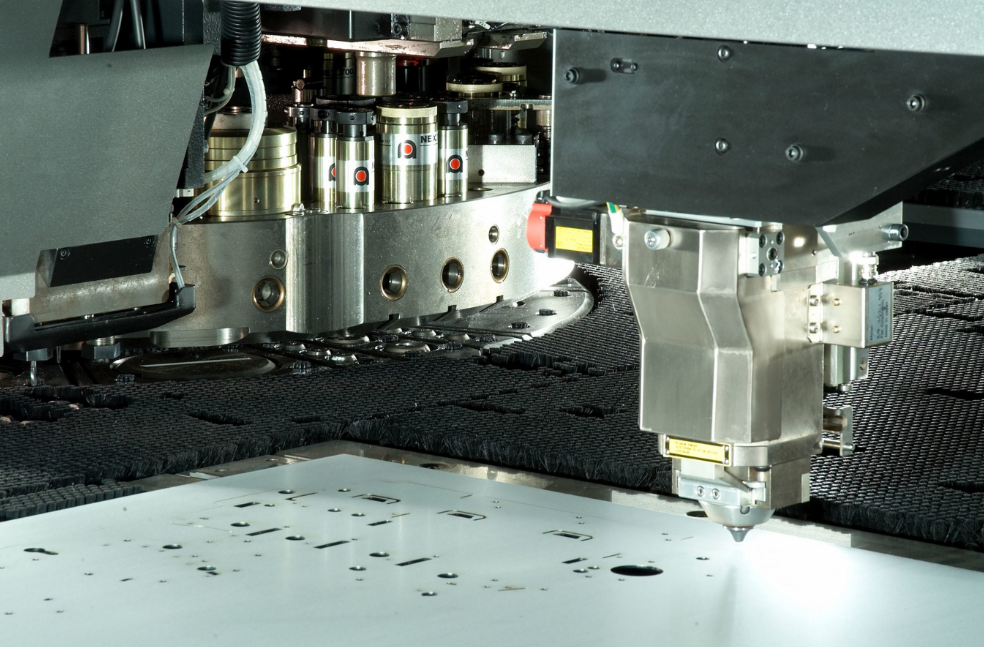

Accuracy is one of the most important things in metal fabrication, as even a one-millimetre difference can ruin your efforts to build a device or equipment. Laser cutters are unmatchable when it comes to accuracy. Whether you want the simple cuts or cutting in some complex patterns, you just need to program the cutters; they will accurately cut the metals with perfection.

If you are building medical testing devices, you must make sure that every cut is clean and perfect without even an error of a nanometer.

Besides that, metal laser cutting machines also create smooth edges and clean finishing. This cutting technique also reduces the waste because the metal particles burnt or melted during the process. That is how it is also less harmful to the workers.

Less energy consumption

The efficient laser cutting machines consume less energy to cut the metals compared to other cutting machines. You can save up to 5times of energy by using these machines due to their sharp and accurate cutting. Besides saving electricity, laser cutters are also environmentally friendly as they don’t pollute the environment.

Consistency

It doesn’t matter how many pieces you want to cut; once you have programmed a cutting machine, it will ensure the same cuts as many times as you need. That is why people prefer laser cutting and punching machines.