When seeking the right stainless steel fabricators for your project, attention to detail and specific criteria are crucial. Stainless steel fabrication involves precise techniques and materials, making it essential to choose a fabricator who can deliver high-quality results.

Here’s a focused guide on what to consider to ensure you hire the best professionals for your needs.

1. Specialisation in Stainless Steel

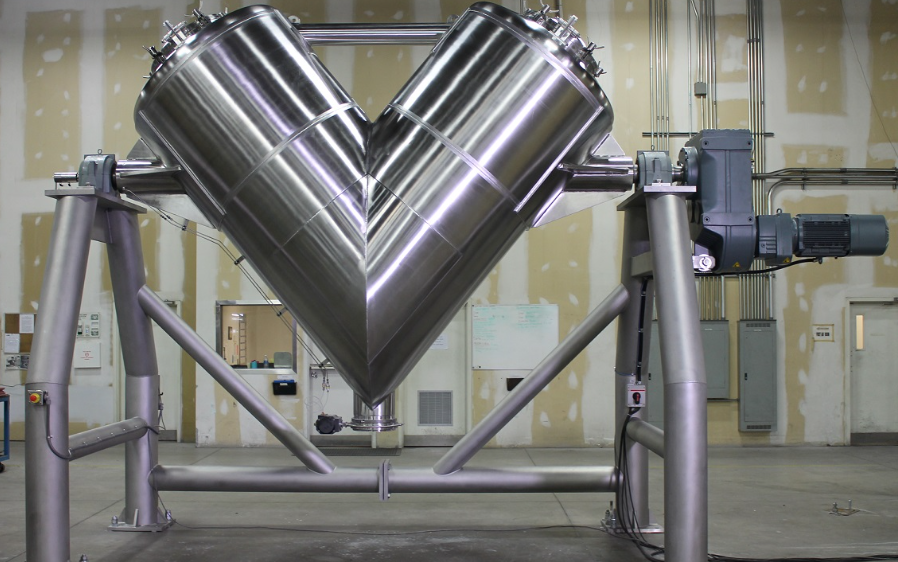

While many fabricators work with various metals, it’s important to find one that specialises in stainless steel. This material has unique properties, such as resistance to corrosion and strength, which require specific handling and techniques. Look for fabricators with a proven track record in working with stainless steel, as they will be familiar with the nuances of welding, cutting, and finishing that ensure durability and functionality.

2. Advanced Fabrication Techniques

The quality of your final product depends on the fabrication methods used. Ensure the fabricator employs advanced techniques such as CNC machining, precision laser cutting, and TIG welding. These methods offer higher precision and better results compared to traditional methods. Fabricators with up-to-date technology and machinery can handle complex designs and achieve finer finishes, which is crucial for intricate projects or high-specification applications.

3. Experience with Similar Projects

Check if the fabricator has experience with projects similar to yours. For example, if you need custom stainless steel countertops, find a fabricator who has successfully completed similar installations. Experienced fabricators will be able to provide references or case studies of previous work. This experience is especially relevant if you have specific requirements, such as custom dimensions or unique design features.

4. Industry Certifications and Standards

Compliance with industry standards is non-negotiable. Ensure the fabricator adheres to relevant standards such as ISO 9001 for quality management or other industry-specific certifications. These certifications indicate that the fabricator follows rigorous processes and maintains high standards of workmanship. Additionally, check if they comply with local regulations and safety standards, particularly if the fabrication involves structural components.

5. Proven Reputation and Client Feedback

A fabricator’s reputation can often be gauged from client feedback and industry reputation. Look for reviews from past clients or ask the fabricator for references. Positive feedback and repeat business are good indicators of reliability and quality. Additionally, industry awards or recognitions can reflect a fabricator’s standing in the industry and commitment to excellence.

When hiring stainless steel fabricators, focus on their specialisation, advanced techniques, project experience, industry standards, reputation, and customisation capabilities. These factors ensure you partner with a fabricator who can deliver high-quality, precise, and reliable results for your stainless steel projects.